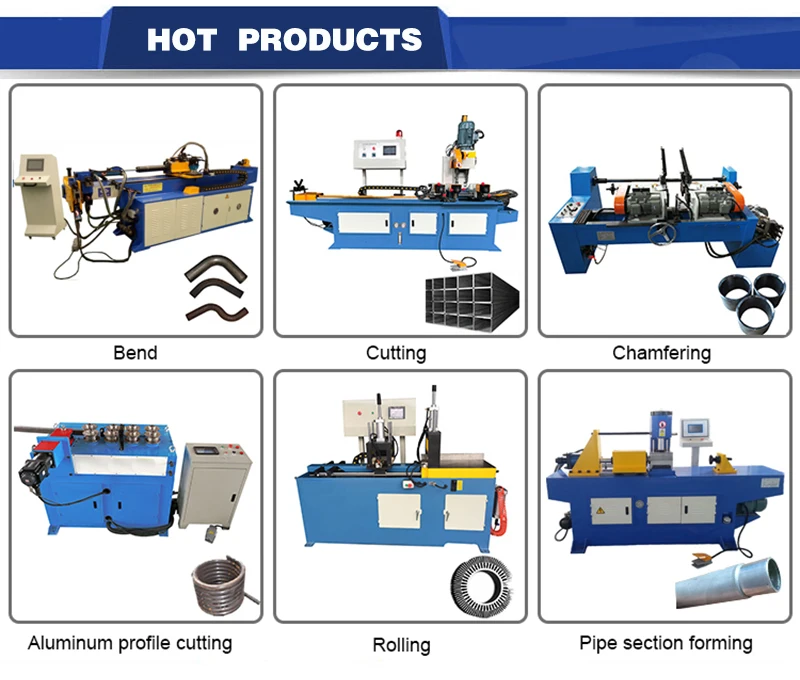

pipe bending machine cnc mandrel for bending square copper stainless steel DW38CNC

Regular price

$15,000.00

$15,000.00

ONLY LEFT

Notices:

1. Please purchase goods before contact me,because a lot of goods weight limit,we can't delivery by sea shipping CIF or FOB delivery trading way.we provide wholesale services,Please before decided to buy goods,be sure to contact me.

2. If you choose "seller's shipping method'',we will arrange the shipment by sea and delivery it to your nearest seaport.

3. We also have other larger capacity machines, please contact us if you need them.

Technical Data of pipe bending machine

|

Main specification |

DW38CNC-2A-1S |

|

|

Max bending capacity |

Φ38mm X 2mm |

|

|

Max bending radius(1) |

R180mm |

|

|

Min bending radius(2) |

According pipe diameter |

|

|

Max bending degree |

190° |

|

|

Max feeding length(3) |

2500mm |

|

|

Feeding method |

Direct deeding/clamping feeding |

|

|

Working speed |

Bending speed |

Max 150°/s |

|

Rotary speed |

Max 200°/s |

|

|

Feeding speed |

Max 1000mm/s |

|

|

Accuracy |

Bending accuracy |

±0.1° |

|

Rotary accuracy |

±0.1° |

|

|

Feeding accuracy |

±0.1mm |

|

|

Information inputting method |

Working value(Y,B,C) |

|

|

Bending method |

Hydraulic bending |

|

|

Rotary servo motor power |

750w |

|

|

Feeding servo motor power |

1kw |

|

|

Max storage unit (4) |

1000groups |

|

|

Motor power |

4kw |

|

|

Max oil pressure |

12 Mpa |

|

|

Machine weight |

1500kg |

|

|

Machine size |

3860x720x1230mm |

|

|

Note:(1) (3)according to customers' requirement (2)According to tube diameter.(4)Extendable |

||

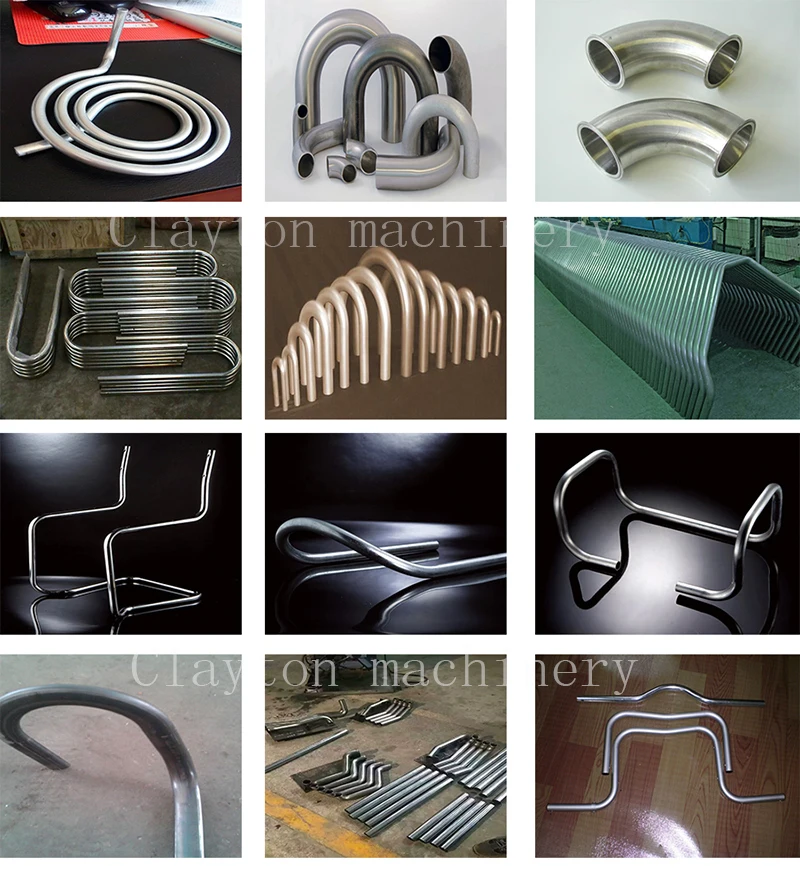

Features of pipe bending machine

1. Automatic recognition of power in machine and work piece, the processing is both quick and good

2. Slow returning core, boosted by barrow, imporving the apprearance of the angle.

3. The whole operation is in the computer, simple, quick and correct

4. Picturized programming system: draw and modify on the stereo pipe image on the screen, makes the operation

simple,

quick and correct

5. Rebound test: comparison test on the features of lots of pipe materials

6. Single-step debugging function- a careful observe on the deformation of the pipe material during the trail

manufacture of dies.

7. Automatic drawing of the graphics of dies-clear help to develop new products

8. Over-all inspection: hydraulic/electrical circuit/ driving systems, adsence of phase in motors/inversion,

voltage, temperature, oil pressure, and automatically diagnose the troubles

9. Passwords, keys, working hours/ recordings of quantities, are applied to management of production

Hydraulic pipe bending machine details

Our service

|

1. One year guarantee for whole machine |

|

2. 24 hours technical support by email |

|

3. Calling or door-to-door service |

Question and answer:

1.Q: Are you a manufacturer or a trading company?

A: we are a direct marketing company. Cedar is our trademark. We do pipe processing machinery.

2. Q: how do you choose your machine

A: you must tell us the following details

How much control do you want to bend

How much the thickness

What material

How much is bent

Of course, there are drawings.

3.Q: what about your machine quality and after-sales service?

A:Our company quality assures safety is the first, many old customers, the after-sale service is the service for you wholeheartedly.

4.Q: where did your factory get there?

A:Our factory is located next to zhangjiagang city (Shanghai) under the jurisdiction of suzhou city. You can fly directly to Shanghai hongqiao airport or PVG airport. You are welcome to visit our humble home.

people are currently looking at this product

Estimated delivery time 14-30 days

Guaranteed Safe Checkout